Articles

Vehicle launches are peak periods for quality management challenges. Data shows that despite technological advances, traditional interior and exterior components from suppliers remain the main focus of containment actions at OEM assembly plants.

Vehicle launches represent a critical project phase where operational quality management faces its greatest challenges. Analysis of supplier quality data reveals a persistent pattern: long-established interior and exterior vehicle components manufactured by suppliers continue to dominate containment actions at OEM assembly plants despite advancing manufacturing technologies.

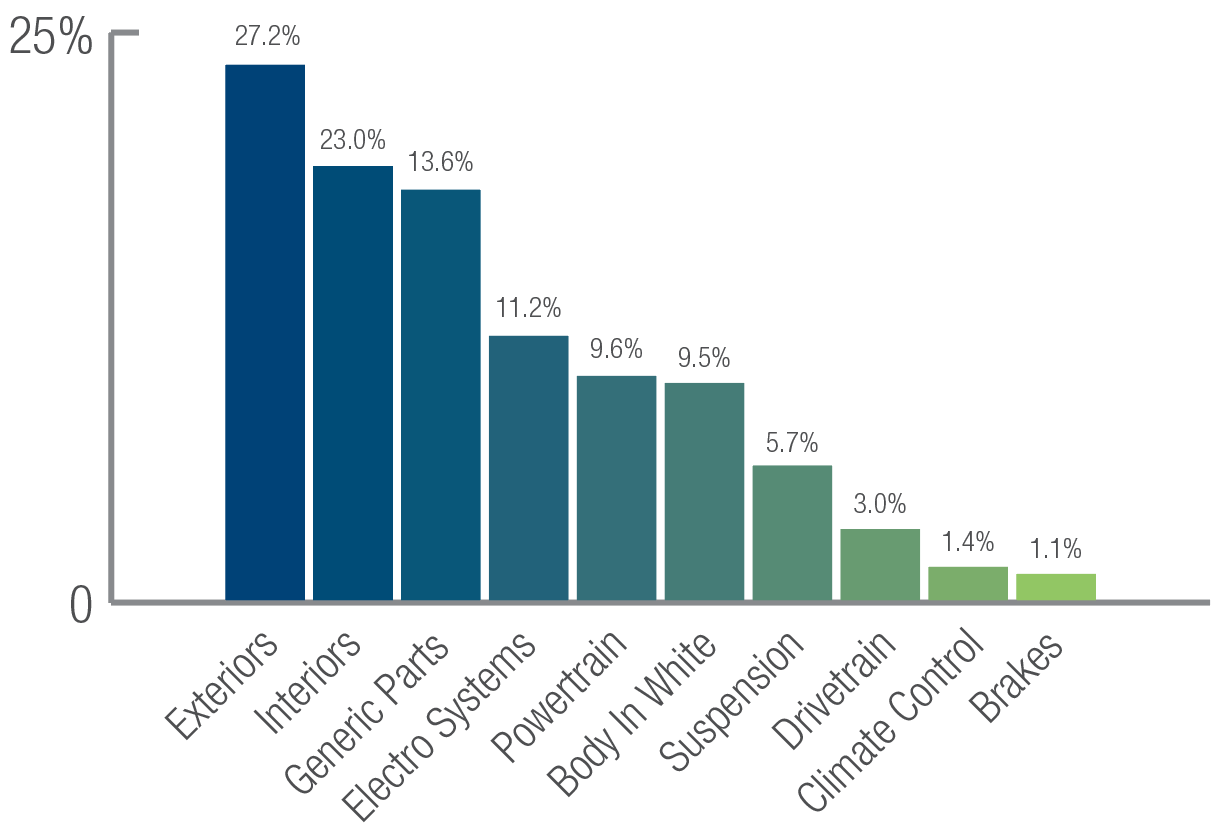

Drawing from TRIGO’s global quality management database, which tracks real-time containment services, this analysis focused on data from the second quarter of 2024, coming from 17 OEM assembly plants in 7 countries, encompassing quality containment actions across 229 unique suppliers and 57 different component categories. The findings demonstrate that the components most subject to quality issues are exterior components (27.2%) followed by interior parts (23.0%) and generic joining components parts (13.6%).

Breakdown Of Quality Issues Per Vehicle System

Analysis of quality data reveals three distinct tiers of vehicle system challenges:

Major Occurrence Group (>17%): Led by exterior components, interior assemblies, and generic joining components, representing the highest frequency of quality issues.

Moderate Occurrence Group (9-12%): Contains electrical and electronic systems, powertrain components, and body-in-white structures, showing intermediate frequency of quality challenges.

Minor Occurrence Group (<6%): Comprises suspension and steering systems, drivetrain components, climate control units, and braking systems, displaying lower but notable quality incidents.

Based on this study, this white paper explores three critical aspects of modern automotive quality management:

This analysis not only highlights current challenges but also provides insights into how emerging technologies and methodologies are reshaping quality management in the automotive industry.

A. Current state of Electronic & Electrical Systems (E&E)

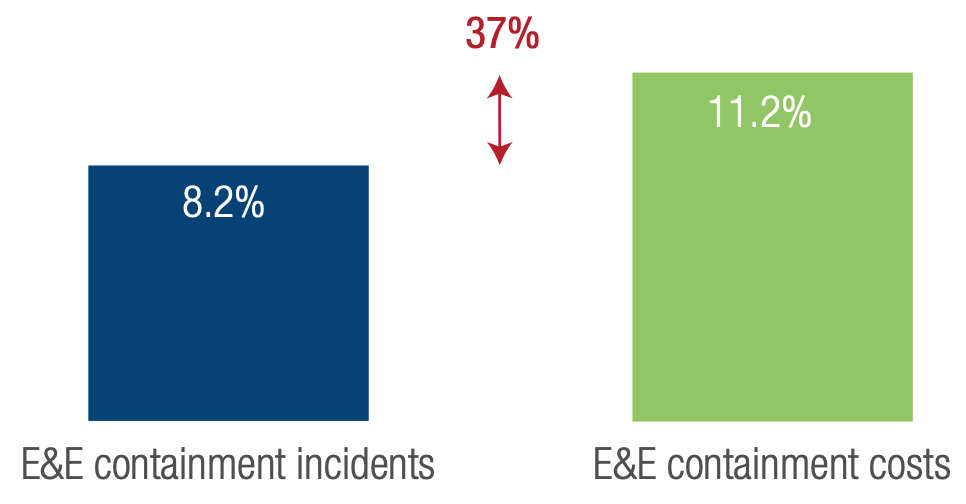

Further analysis of the data reveals an important insight regarding Electric & Electronic Systems (E&E): while they represent 11.2% of total containment costs, they account for 8.2% of the total number of incidents. This higher containment cost-per-incident ratio can be attributed to the complexity of resolving electronic issues, particularly the frequent need for re-flashing operations. Unlike mechanical components that may require simple sorting or rework, electronic systems often demand specialized equipment, more trained personnel, and time-intensive software updates to address quality concerns.

As vehicles continue to incorporate more complex electronic systems, this trend of increasing Electric & Electronic related containment actions and their associated costs is expected to become even more pronounced.

Electronic & Electrical vs. Other Systems: Containment Analysis become even more pronounced.

Electronic & Electrical vs. Other Systems: Containment Analysis

B. Electronic Control Units (ECUs): Rising demand during new vehicle launches of the ECU’s Software updates

a) Overview of modern vehicle ECUs

Given the unique challenges posed by E&E systems, particularly in terms of specialized equipment and expertise requirements, understanding overall E&E architecture and Electronic Control Units (ECUs) for optimizing containment actions is essential for reducing overall quality management costs, as these components are becoming the backbone of modern vehicle electronics and present distinct quality challenges.

Today’s vehicles may contain around 50 ECUs, controlling essential functions such as engine and power steering, comfort features like power windows, seats, and HVAC (Heating, Ventilating and Air Conditioning), as well as security systems including door locks and keyless entry. Additionally, ECUs manage passive safety features such as airbags and basic active safety features like automatic emergency braking. With the increasing sophistication of modern vehicles, the quality of ECUs significantly influences safety, performance, and customer satisfaction.

Modern Electronic Control Units integrate advanced software algorithms with complex hardware platforms. Ensuring hardware-software integration presents significant challenges, primarily due to the diverse ecosystem of component suppliers, multiple software versions, and varying system configurations. This complexity has driven automotive manufacturers to pursue a strategy of ECU consolidation, aiming to simplify vehicle development by reducing the total number of control units per vehicle.

b) The 4 critical Electonic Control Units requiring re-flashing

At TRIGO, we have identified the top four car control units frequently requiring re-flashing at the OEM production plant:

a) Cost implications & key operational challenges

A common action following a quality incident involving ECUs is re-flashing both the stock at the OEM and the in-transit components. This process is complex for several reasons:

b) Update protocols

Additionally, re-flashing process implementation can vary significantly depending on the communication protocols that need to be implemented:

At TRIGO, we have developed specific service solutions to optimize the cost of traditional re-flashing operations, which can easily amount to tens of thousands of dollars when performed at the OEM. By addressing the challenges mentioned above, we aim to enhance the efficiency and reliability of ECU re-flashing processes, ensuring better quality control and cost management for both automotive manufacturers and component suppliers.

A. Current state analysis

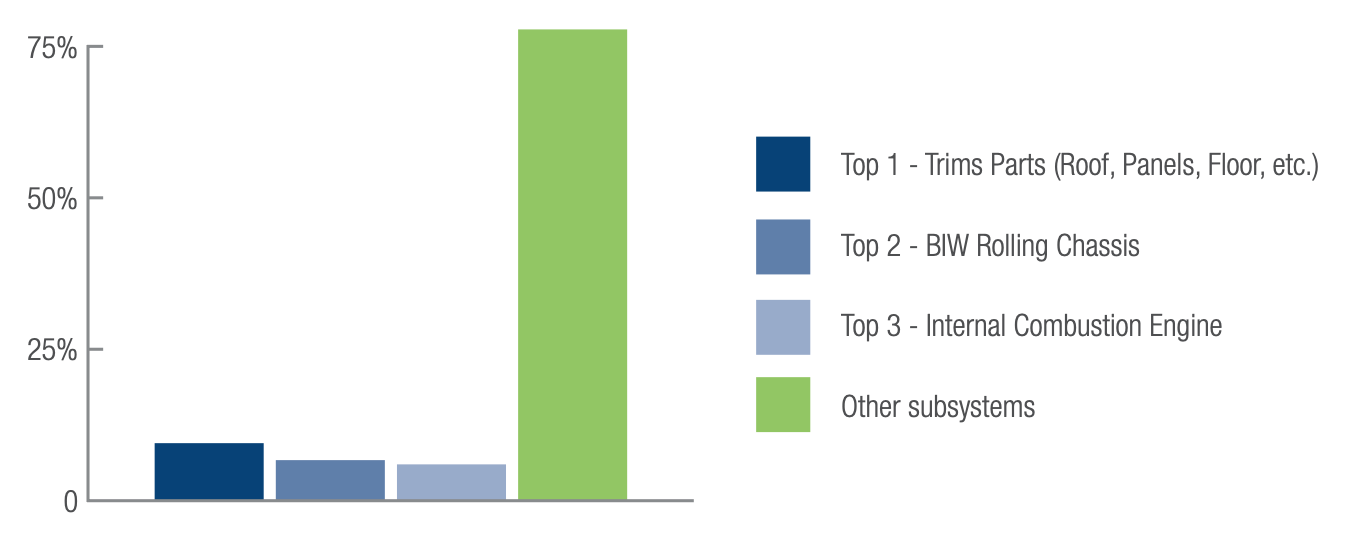

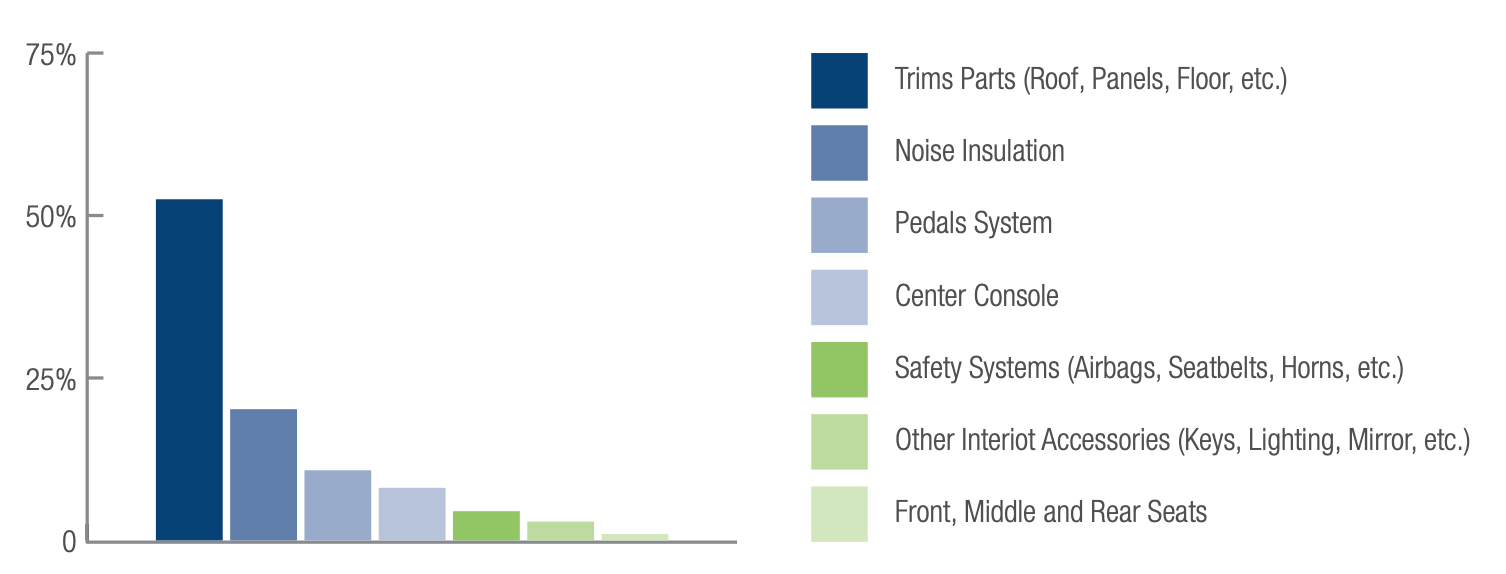

Interior components from suppliers play a vital role in shaping how drivers and passengers experience a vehicle – from perceived quality to safety and practical functionality. TRIGO’s research shows these supplier components consistently lead to more containment actions at OEMS than any other vehicle parts throughout the production lifecycle.

Diving deeper into the data, Interior Trim Parts emerge as the most problematic category, responsible for 17.5% of quality issues globally and 52.5% of interior quality issues that require containment actions. This category encompasses roof components, panels, and flooring materials. This incident rate reflects the growing complexity of automotive design and technology, highlighting the need for suppliers to develop more sophisticated quality control processes specifically for these interior elements.

Top 3 Subsystems Generating Containment Actions

Quality Incidents Breakdown by Interior Component Type

B. Defect classification

While automakers implement comprehensive quality checks during new model launches, before vehicles reach customers, certain issues can still slip through. This is particularly true for aesthetic defects – while they may not compromise the vehicle’s operation, they can significantly impact customer satisfaction and their perception of the vehicle’s overall quality.

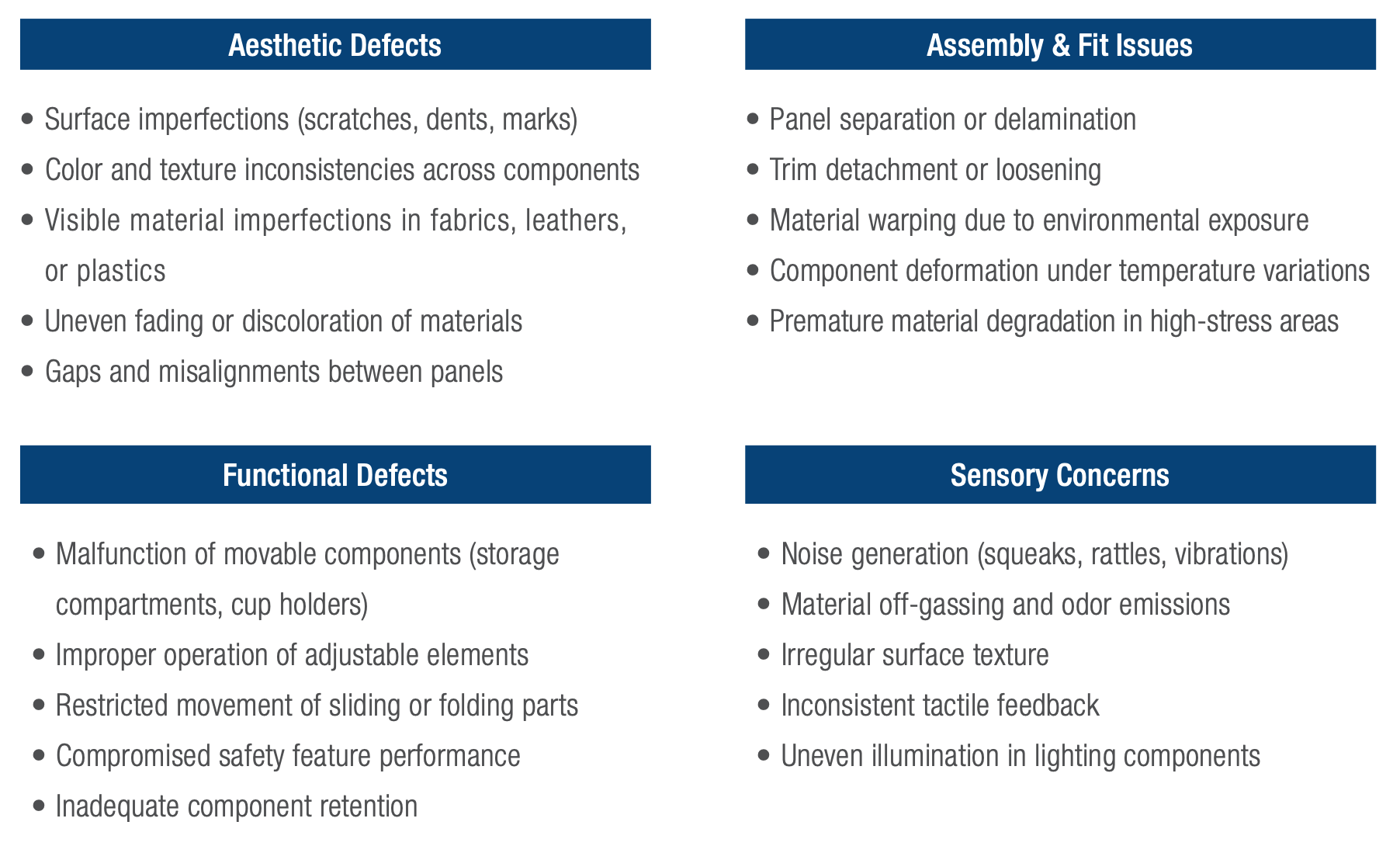

The defects that TRIGO controls for interior parts can be broken down into these types:

A. Current limitations and needs

The automotive interior components industry still faces challenges in maintaining consistent quality control across high-volume production environments. Traditional automated optical inspection methods often struggle with complex geometries, subtle defects, and the need for comprehensive multi-angle analysis. This has created a pressing need for more sophisticated inspection solutions that can deliver both precision and scalability.

AI-powered visual inspection systems have emerged as a transformative solution, offering several key advantages over conventional methods:

B. AI-Powered Solutions

TRIGO, through its subsidiary Scortex, has developed a cutting-edge AI-based inspection solution specifically designed for these challenges. The system demonstrates the practical application of refined deep learning algorithms in two key areas:

Complex Surface Defect Detection:

Multi-Point Inspection:

This integration of advanced visual inspection technology represents TRIGO’s commitment to developing innovative quality control solutions that address the evolving challenges in automotive component manufacturing, while maintaining high throughput rates and consistent quality standards.

Prioritize interior & exterior components supplier oversight:

Adopt AI-Driven inspection solutions for interior parts quality control:

Plan for Electronic & Electrical Systems containment actions: