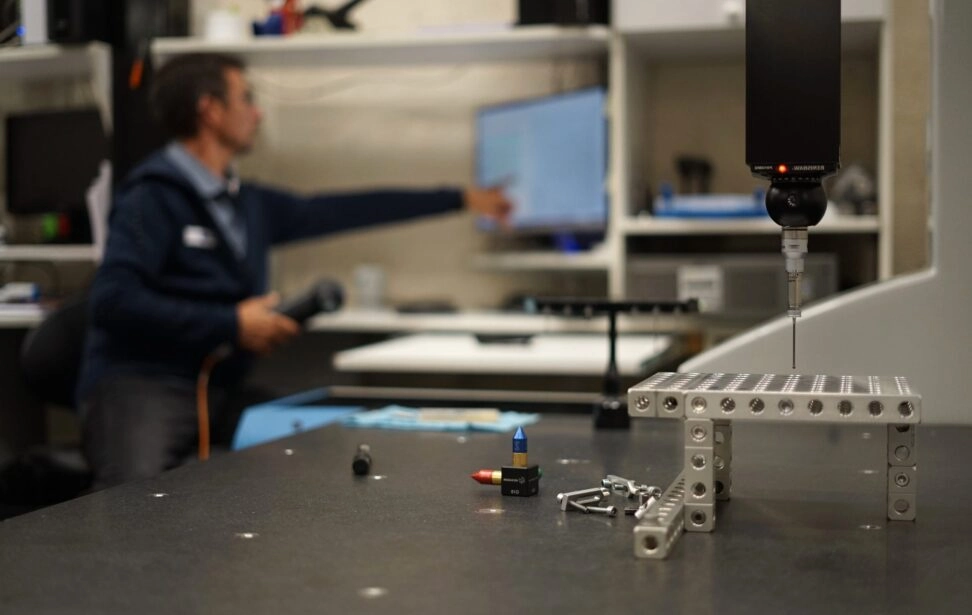

Precision-Driven Incoming Material Inspection: Catch Defects Before They Reach the Production Line.

We meticulously assess raw materials and components to ensure they meet exact specifications, reducing waste, rework, and costly delays.

Our Quality Inspection services provide the assurance you need to meet your customer’s expectations every time. With meticulous attention to detail, we identify defects, verify specifications, and ensure full compliance with industry regulations. Leveraging advanced technology where possible, our experienced inspection teams detect issues early, optimize production efficiency, and minimize risks. We prioritize quality at every stage, helping you build trust, enhance customer satisfaction, and protect your brand’s reputation - ensuring your products stand out for their reliability and excellence.

We meticulously assess raw materials and components to ensure they meet exact specifications, reducing waste, rework, and costly delays.

Our experts detect deviations in welding, machining, painting, and assembly before they escalate, keeping your production flawless and compliant.

We conduct rigorous functionality, safety, and aesthetic evaluations, ensuring every product leaving your facility meets stringent quality benchmarks and customer expectations.

We verify that every product is ready, free of defects, and meets all regulatory requirements, ensuring seamless delivery to your customers.

With our proactive quality solutions, you can reduce defects, streamline production, and strengthen your brand’s reputation for reliability.

At a major Canadian engine supplier's facility, we transformed quality control operations for critical connecting rod components, scaling from 9 million to 18 million annual inspections while maintaining exceptional precision. Through systematic process optimization and dedicated quality management, we achieved a remarkable reduction in defect rates from 20% to less than 0.01%, ensuring consistent component reliability for automotive OEM production.

A European aircraft manufacturer's cabin quality program utilized our inspection capabilities in France and Germany. Our team of 10 inspectors implemented work unit management processes, using our technology to inspect 14,000 cabin components monthly. The program reduced final assembly line findings by 75% and reduced seat release lead times from 4 days to 1 day, achieving 100% conformity of the installed cabin element.

We greatly appreciate the service provided within our scope. Responsiveness, mindset, competence, and initiative are all present. We are fully satisfied with our collaboration.

Excellent team members. Very responsive and consistently go above and beyond in addressing any of my questions and concerns.

Once the need for visual inspection was realized internally, we contacted the TRIGO Group. The professional service of TRIGO’s quality inspectors with optimized time management resulted in a greater level of productivity. After several months of cooperation, the results are satisfactory and we are planning to externalize this activity on other products as well.

Through accurate TRIGO inspections, it was possible to achieve a reduction in defects at the customer’s line within a short time period. Due to the ongoing comparative analysis driven by the customer's quality index, our overall quality level has been significantly improved. In quality discussions with the customer, TRIGO provides an objective and professional assessment, avoiding biased decisions while contributing to more balanced and fair communication.

Through accurate TRIGO inspections, it was possible to achieve a reduction in defects at the customer’s line within a short time period. Due to the ongoing comparative analysis driven by the customer's quality index, our overall quality level has been significantly improved. In quality discussions with the customer, TRIGO provides an objective and professional assessment, avoiding biased decisions while contributing to more balanced and fair communication.

TRIGO Group has proven to us that they are a customer-focused, extremely dependable quality inspection company. Their ability to deploy professional personnel quickly, along with handling the constant changes in our plant and providing exemplary communication, with little direction from us, demonstrates their experience and competence at the highest level.