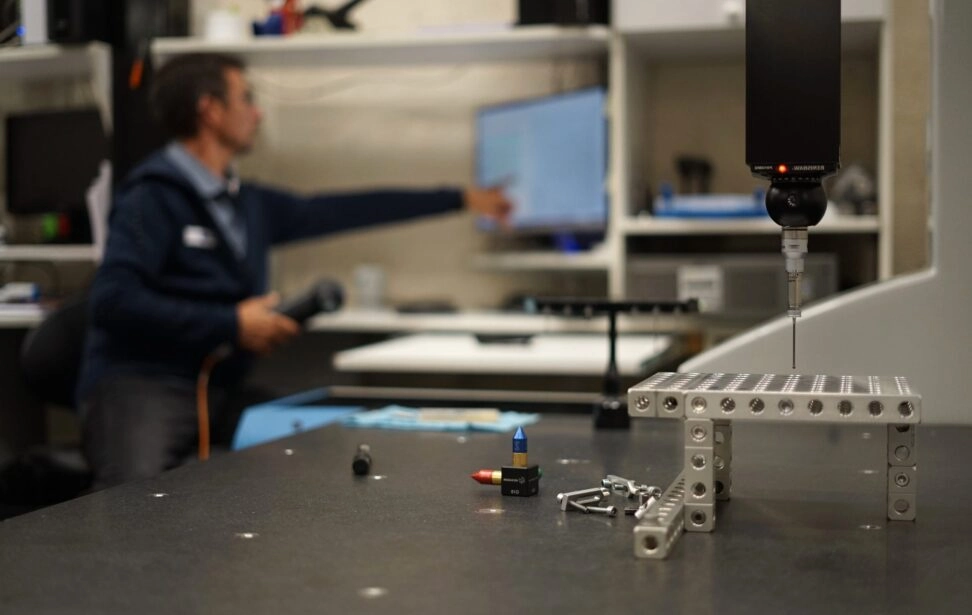

Source Inspection

When you are launching a new product, transferring work or qualifying new suppliers, TRIGO source inspection expertise steers you smoothly through the bottleneck of on-demand, last-minute or urgent source inspection. Covering all commodities, our network of inspectors, working with our TRIGOSCOPE software, will solve your issues.