Articles

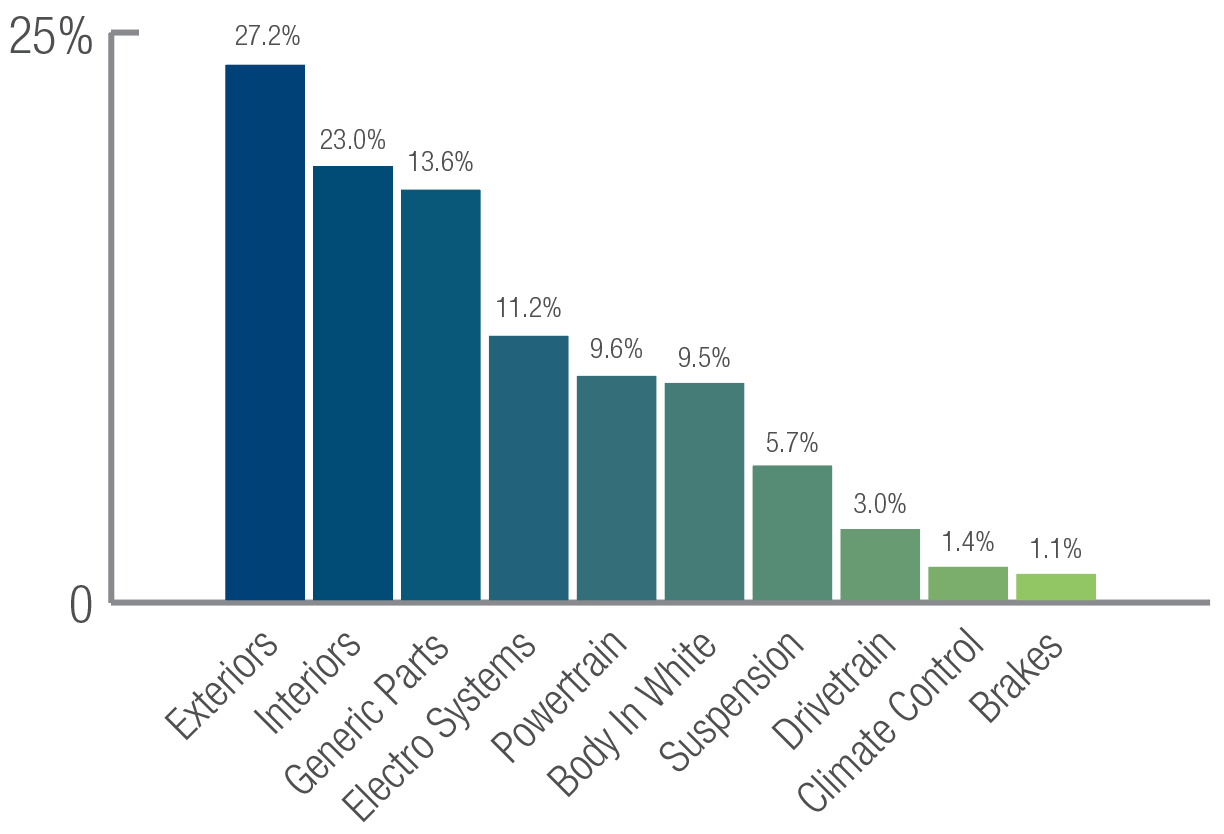

In a recent study conducted across 17 assembly plants in 7 countries, TRIGO, the global leader in quality control and management for the transportation industry, examined the costs of various failures affecting automakers at the time of vehicle launches. The findings showed that the majority of quality failures concern exterior components (27.2%) and interior components (23%), followed by generic assembly parts such as fasteners, adhesives and screws (13.6%).

Download the white paper here.

Analyzing data from 229 suppliers, TRIGO’s study revealed that certain “legacy” components, particularly interior trim parts such as ceilings, panels and floor coverings, account for 23% of the quality defects observed making them one of the most problematic categories.

Other sub-assemblies such as seats, center consoles, safety systems (airbags, seatbelts), interior accessories (rear-view mirrors, lighting, and keys), sound insulation and pedal systems also frequently show defects directly impacting the user experience.

On-board electronics are of growing concern. ECUs (Electronic Control Units) central to the control of modern vehicle costs have risen sharply. Despite being involved in only 8.2% of incidents examined by the study, they accounted for up to 11.2% of quality assurance costs.

Vehicles can incorporate up to 50 Electronic Control Units (ECUs), responsible for controlling critical functions including engine performance, power steering, and safety systems as well as comfort and convenience features.

Vehicles can contain up to 50 Electronic Control Units (ECUs), responsible for controlling critical functions from engine performance, power steering, and safety systems to comfort and convenience features. The increased provision of software updates delivered by reflashing requires specialized equipment and advanced technical skills, often leading to production interruptions.

Ricard Lou, Director of Data Solutions at TRIGO, explains: “We are witnessing a shift in quality issues towards high value-added parts, particularly electronic systems. The use of artificial intelligence represents a promising solution for adapting industrial processes to these new quality requirements and optimizing industrial performance.”

Two major areas of noncompliance have been highlighted. On the one hand, ECUs require equipment that is often incompatible with industrial production rates, resulting in significant additional costs. Four systems account for the majority of reprogramming incidents: the engine module, transmission control unit, body module, and infotainment unit. Updates are further complicated by vendor lock-in.

Defects in the passenger compartment such as a poor fit or subpar visual finish or tactile feel can directly impact the brand’s image. While they do not affect vehicle functionality, it may keep customers from buying it. In an ultra-competitive market, where the on-board experience is increasingly a major differentiator, such discrepancies now prove as strategic as technical performance.

TRIGO believes that to identify, correct and gradually eliminate quality issues in the automotive industry, technology must be used pragmatically at several levels. First, traditional quality checks must be maintained for all types of components. Such checks may, however, be enhanced through technical means. Second, the growing failure rate of electronic systems must be addressed through increasingly sophisticated diagnostic and reflashing capabilities. Finally, artificial intelligence is quickly becoming a strategic lever for optimizing quality control on an increasingly wide range of components including electronics.

On a technological level, TRIGO is increasingly integrating breakthrough innovation: automated optical inspection using artificial intelligence, known as Spark. Developed by TRIGO’s subsidiary Scortex, this technology analyzes up to 3 parts per second in real time, with constant precision. In addition to detecting visual defects accurately and uniformly, Spark stands out for its ability to generate and use quality control data to optimize the inspection process and resolve long-term defects.

Beyond defect detection, the structured collection of quality data facilitates pattern analysis to uncover potential deviations, optimize manufacturing processes, and proactively manage compliance risks. The data-driven management offered by Spark helps us make long-term improvements in quality performance while significantly reducing non-quality costs.

Augustin Brochot, Executive Vice-President of TRIGO WEMEA concludes: “In order to secure the quality of components, we recommend strengthening quality controls upstream in the value chain. AI is a strategic lever for improving the detection and resolution of appearance defects on all kinds of components, through automated optical inspection. It also allows us to anticipate non-conformity through prediction models.”

TRIGO is the global leader in quality management services for the automotive, aerospace, railway, and heavy transportation industries. With 10,000 employees in 28 countries, TRIGO offers a comprehensive portfolio of services throughout the supply chain, from production inspection to audit, consulting, engineering, and training. TRIGO develops technological solutions based on artificial intelligence, virtual reality, and data analysis.

Jean-François Kitten – +33 6 11 29 30 28 – jf@licencek.com

Avtansh Behal – +33 7 69 53 08 25 – a.behal@licencek.com

Jérémy Cariddi – +33 7 66 39 75 99 – j.cariddi@licencek.com