Scortex: A TRIGO company. AI-Powered, Automated Quality Inspection for Manufacturing Excellence

Scortex was created in 2016 to automate and make industrial visual inspections, even the most challenging ones, more efficient. Since May 2022, Scortex has been part of the TRIGO Group.

With an experienced team of vision, machine learning, software, and data science experts, Scortex is dedicated to improving manufacturing quality through its AI-powered, automated inspection kit, Spark.

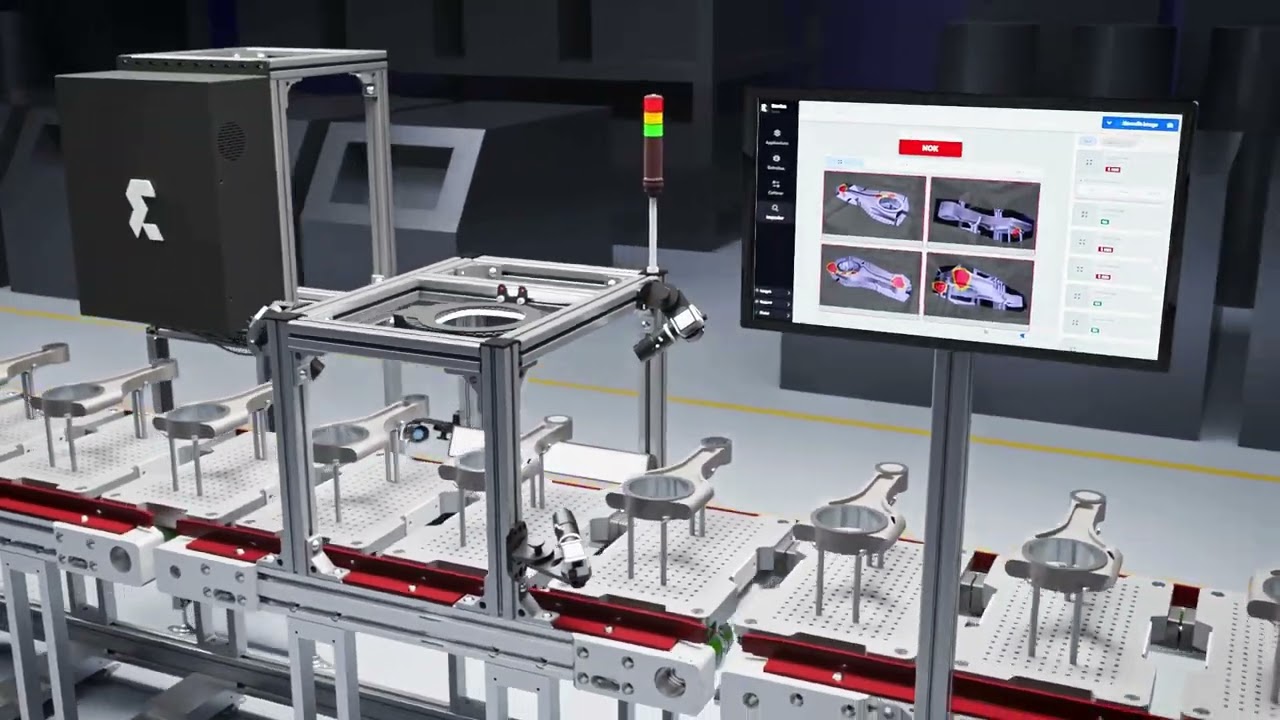

Discover How Spark Revolutionizes Your Quality Inspection

Video

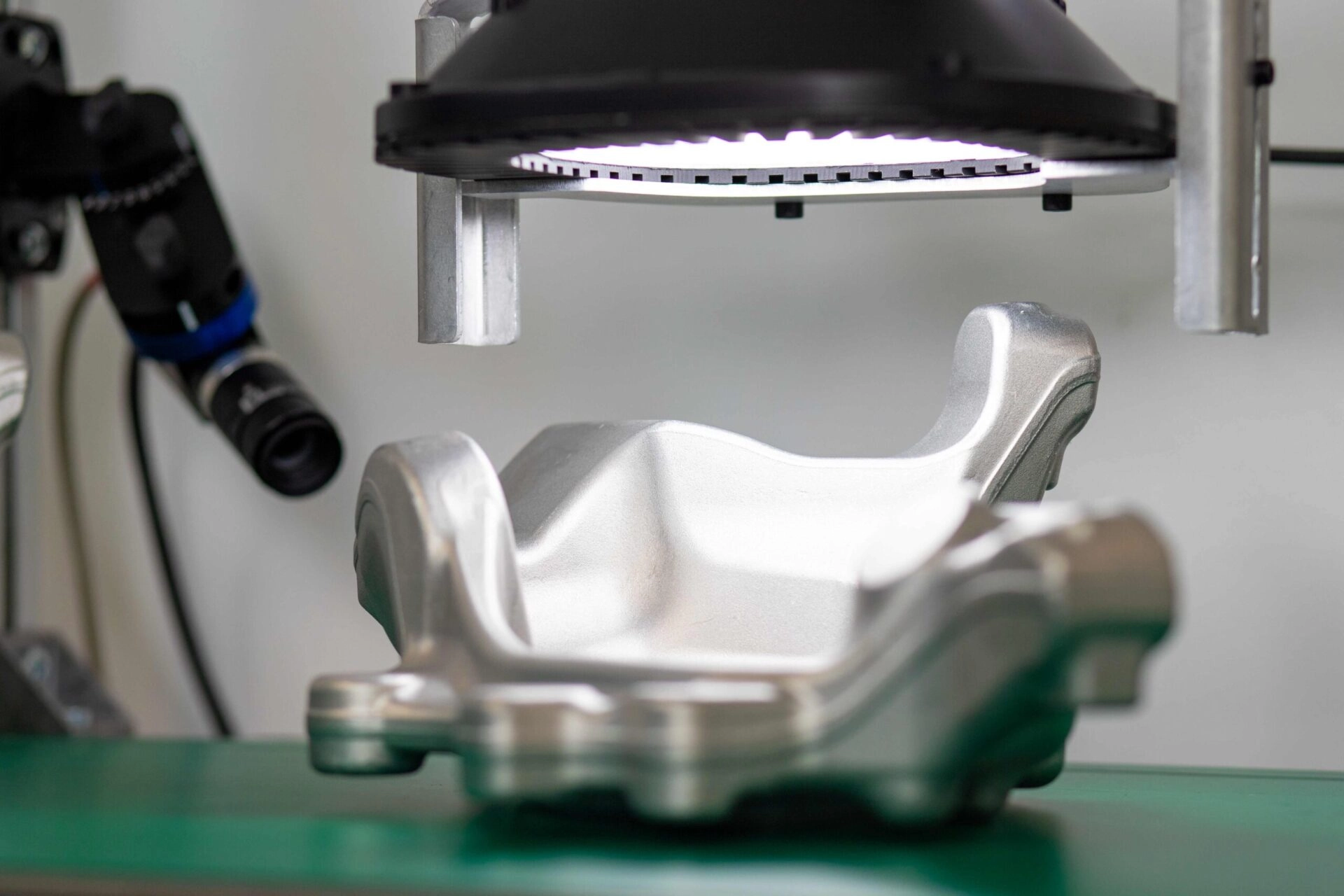

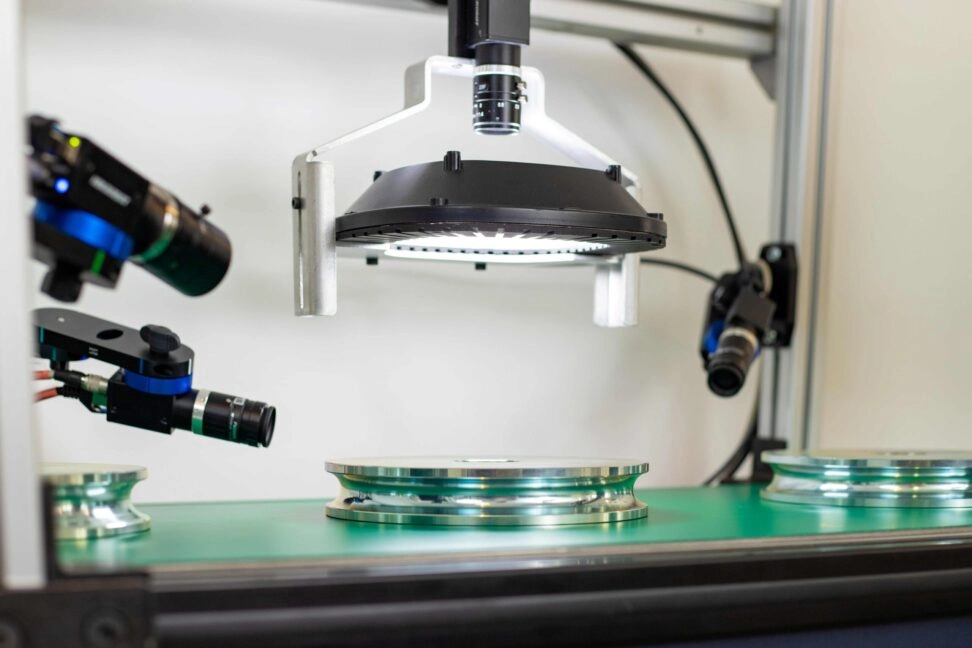

Spark: Detect Defects from Every Angle

Spark uses AI to automate visual quality inspection in factories, with real-time detection of defective products to prevent customer issues. The secure cloud platform allows our experts to help you achieve excellent performance, even for challenging projects, while unlocking valuable insights to improve your manufacturing process.

Why Choose Spark for Quality Control?

Thanks to its AI, Spark detects what others miss.

Spark enhances defect detection with up to 4 cameras, inspecting a large variety of parts including complex and reflective ones. Spark software analysis ensures identification of even the smallest defects, improving precision and reliability.

- Real-time defect detection

Instant decisions, right on the line. - Reliable AI inspection

Consistent, reproducible, drift-free detection. - Scalable to any production line

Fits your parts and constraints. - Data to improve your process

Full traceability and insights to cut to root causes.

Quality Center: Visual Performance Analysis with Expert Support

Gain instant access to your quality data with the Quality Center, designed for efficiency and accuracy.

- Enhanced performance visualization.

- Easily explore data, performance metrics, and alternative approaches with guidance from Scortex experts.

- Effortless reporting-generate real-time reports with pre-structured data, instantly tracking scrap rates and production trends.

- In-depth analysis-View high-resolution inspection images to quickly investigate and resolve production defects remotely.

Voice of the Team

At Scortex, we work to enhance manufacturing performance by providing high-accuracy tools that not only separate compliant from non-compliant parts, but also help teams identify the root causes behind process issues. AI-powered inspection helps quality and production teams agree on demanding appearance criteria and rely on consistent, traceable data for their decisions. Is it exciting work? Absolutely!

At Scortex, our work is driven by the desire to help manufacturers move into Industry 4.0. Every day, we help our clients optimize their quality processes and improve the ergonomics of their workstations.