Boost Efficiency

3 to 20 times faster than manual inspection, eliminating bottlenecks.

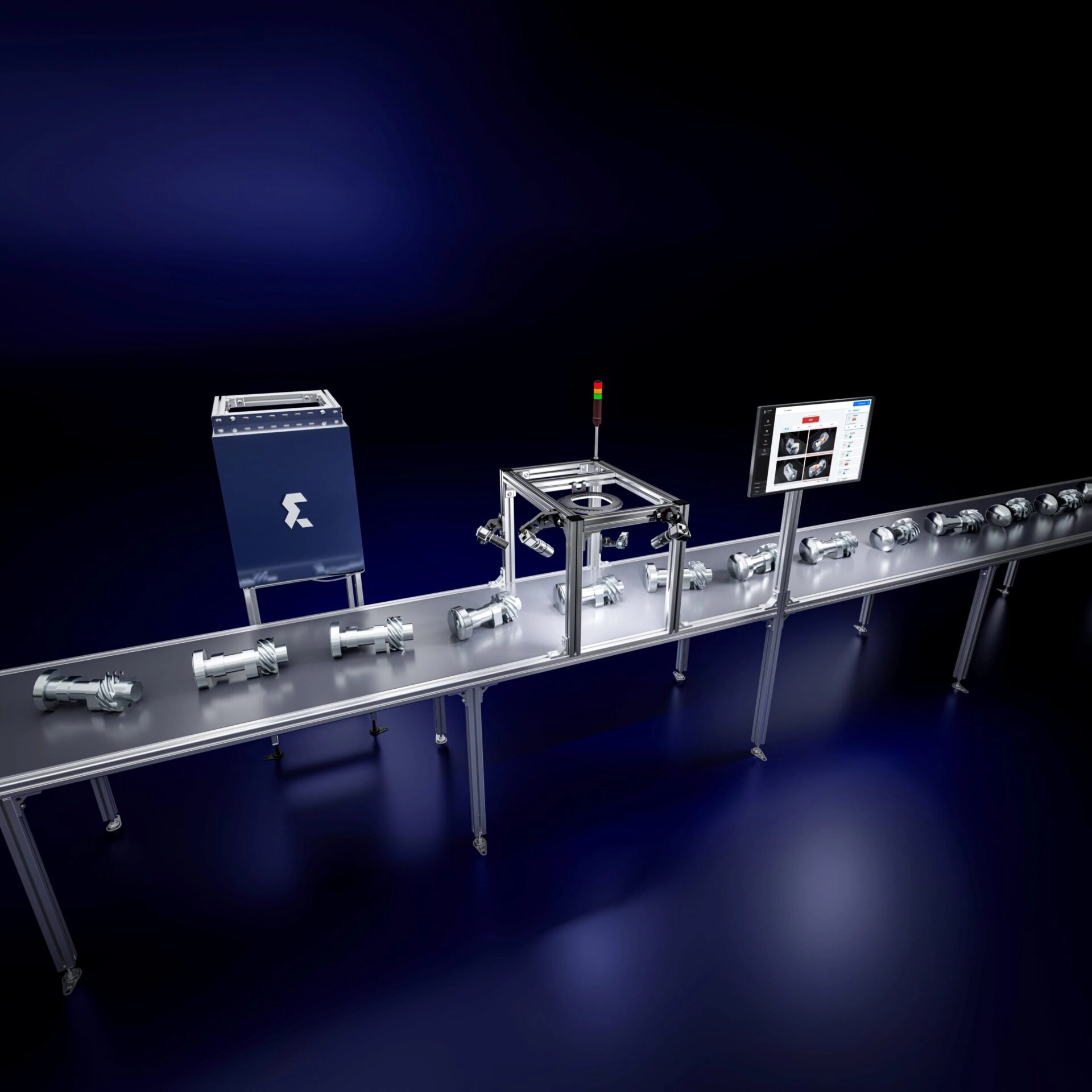

TRIGO revolutionizes quality inspection with Artificial Intelligence and Spark. Spark leverages AI to automate visual quality inspection in factories, instantly identifying defects to reduce customer complaints. Its secure cloud platform enables our experts to support you in achieving top performance, even for complex projects, while providing valuable insights to enhance your manufacturing processes.

Video

Scortex delivers cutting-edge automated visual inspection solutions to address critical manufacturing challenges:

Scortex’s AI-powered technology integrates seamlessly with TRIGO’s comprehensive quality services, offering manufacturers a complete solution for excellence in today’s demanding production environments.

3 to 20 times faster than manual inspection, eliminating bottlenecks.

Detects subtle appearance defects with high precision.

Inspect up to 3 parts per second, even for challenging surfaces.

Real-time quality reports via the Quality Center web portal.

Video

What the factory needed: A machining supplier wanted a reliable way to inspect very small metal parts where manual control was inconsistent.

What Spark delivered:

- Automated inspection of all surfaces at 0.25 seconds per part

- Stable anomaly detection on complex geometries

- Consistent results across >10,000 parts/day

- Full Multi-View coverage (4 cameras) + automatic quality decisions

Impact: Autonomous operation and ROI achieved in <18 months.

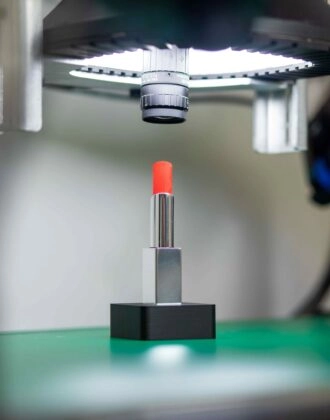

What the factory needed: A global cosmetics brand struggled with defect escapes and operator fatigue on fast lipstick lines.

What Spark delivered:

- 100% inspection of every lipstick (marks, color, deformation)

- AI model trained on anomaly detection to be closer to production line reality

- Stable detection even when products vary in position or orientation

- Seamless integration with existing conveyors

Impact: Reduced manual strain for operators and more consistent detection performance.

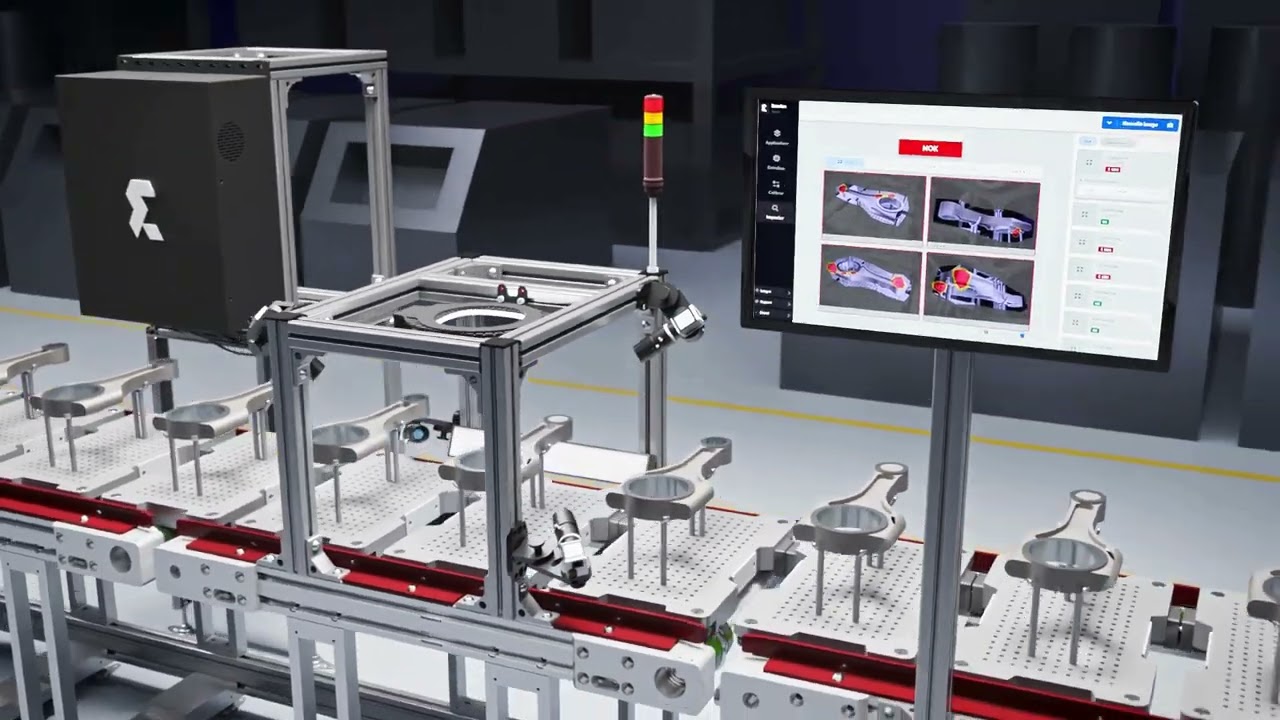

What the factory needed: A Tier-1 automotive supplier faced rising scrap rates (+5%) and inconsistent manual checks.

What Spark delivered:

- Automated inspection for color defects, burrs, deformation, inclusions

- Stable detection across frequent reference changes

- Real-time rejection data enabling process tuning

- Continuous control even at high throughput

Impact: Scrap rate reduced significantly and customer complaints dropped.

What the factory needed: A luxury glass producer needed to detect micro-chips while maintaining throughput.

What Spark delivered:

- Multi-View inspection of bottles at >10,000 units/hour

- Reliable detection of micro-chips and impact marks

- AI adapted to variations in glass thickness and reflections

- Direct integration into the bottling process

- Impact: Zero-defect escapes and full traceability for audits.