You would like to:

- Deploy a continuous improvement approach through a project for the whole company (workshops and offices).

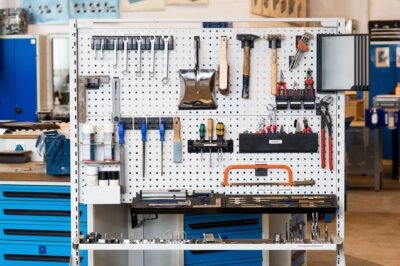

- Use a practical methodology to improve the quality, safety, and productivity issues.

Duration : 2 to 4 days, based on the scope defined during on-site preparation.