Inspection, Rework and Containment of Trucks

Automotive

OEM

CUSTOMER

- Japanese Automotive OEM Assembly Plant – Pick-up Trucks

TARGET

- Optimized production by becoming single-source provider for quality support services

NATURE OF SERVICE

- Contain and rework identified defects at OEM facility to ensure no rejects reach the plant assembly line

TASKS

- Work closely with internal personnel to introduce validated and approved containment methods to identify defects and rework products

- Rearranged inspection process to include improved flow, lighting and safety measures

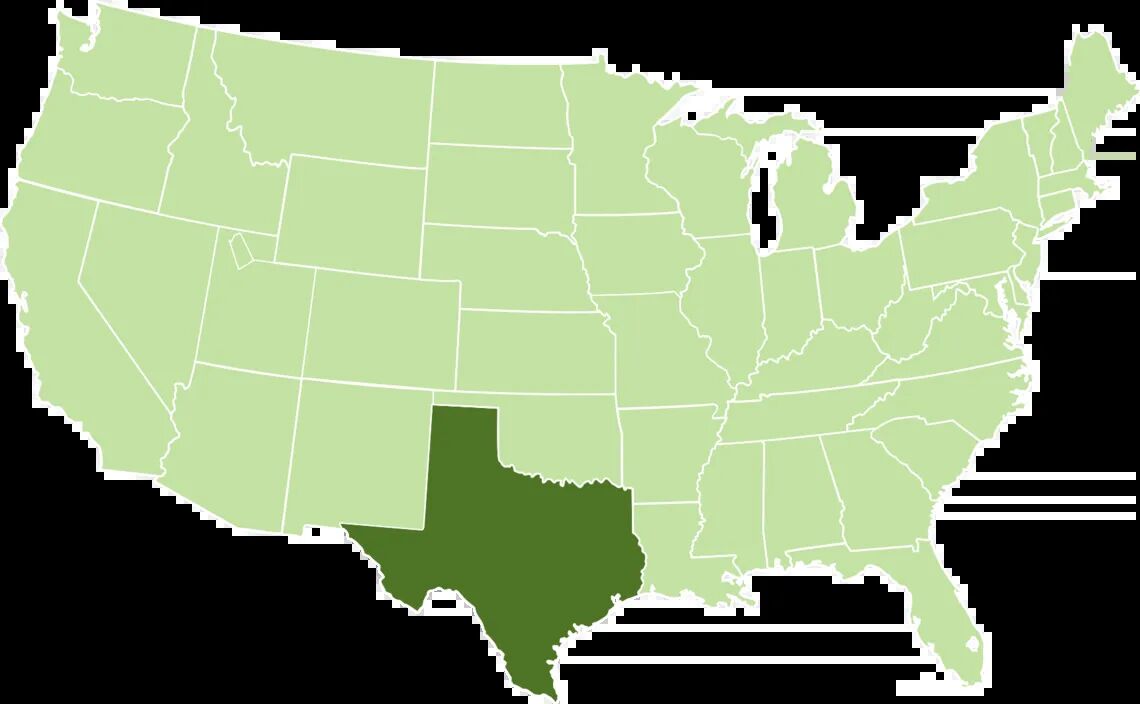

LOCATION

- Texas, USA

KEY FIGURES

- 372 Completed Projects/Missions

- 3,506,299 Parts Inspected

- 355,629 Parts Reworked

- 427,296 Parts Rejected

TEAM

- 1 Site Manager

- 1 Site Leader

- 6-10 Inspectors Daily

KEY ACHIEVEMENTS & RESULTS

- Improved overall inspection process with better and consistent lighting

- Improved efficiency with flow and lighting

- Decreased safety issues with improved lighting