Source Inspection I.

Aerospace and Defense

Supplier

CUSTOMER

- Global aerospace supplier

TARGET

- Enforce corrective orders from OEM

- Address issues with on time deliveries, defects, non-conformities, damage during shipment process

NATURE OF SERVICE

- Source Inspection on all units prior to shipping and again upon arrival for final assembly (lavatories, overhead storage, seating: ATA 25, ATA 44)

- Solutions across the A350, A320, A330 product lines

TASKS

- Set up and conduct training including TRIGO best practices, trouble-shooting

and CI - TRIGO Quality Manager coordinated and managed activities in 6 locations

(Canada / US)

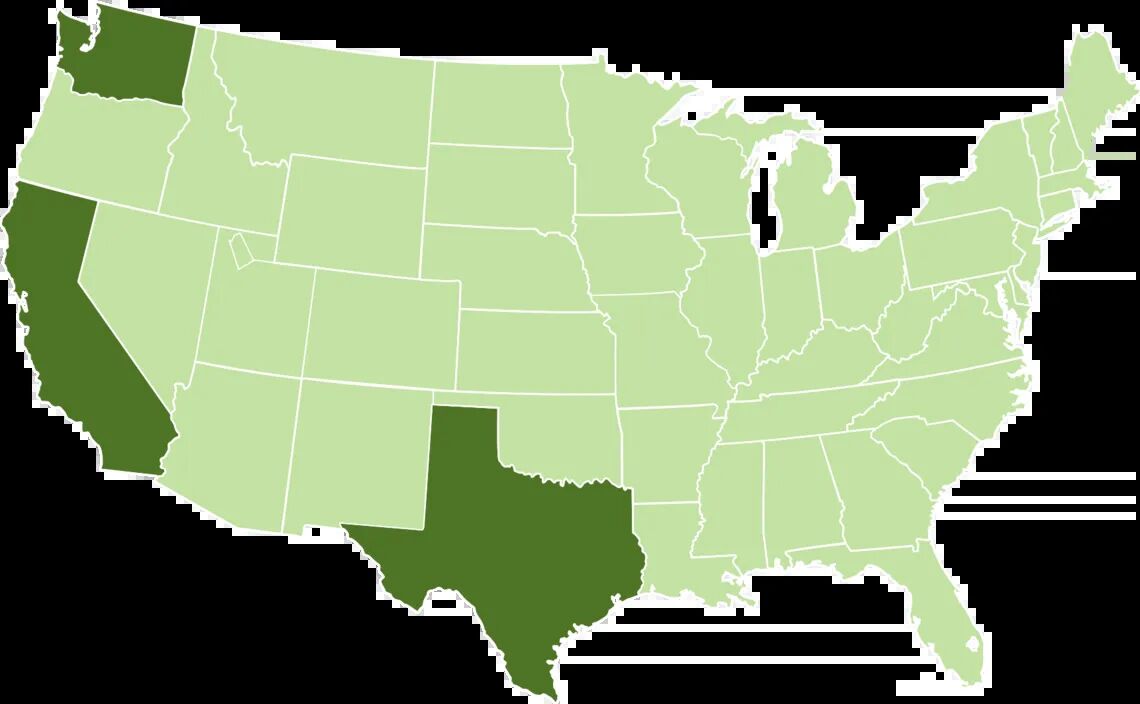

LOCATION 1

- Texas

- California

- Washington

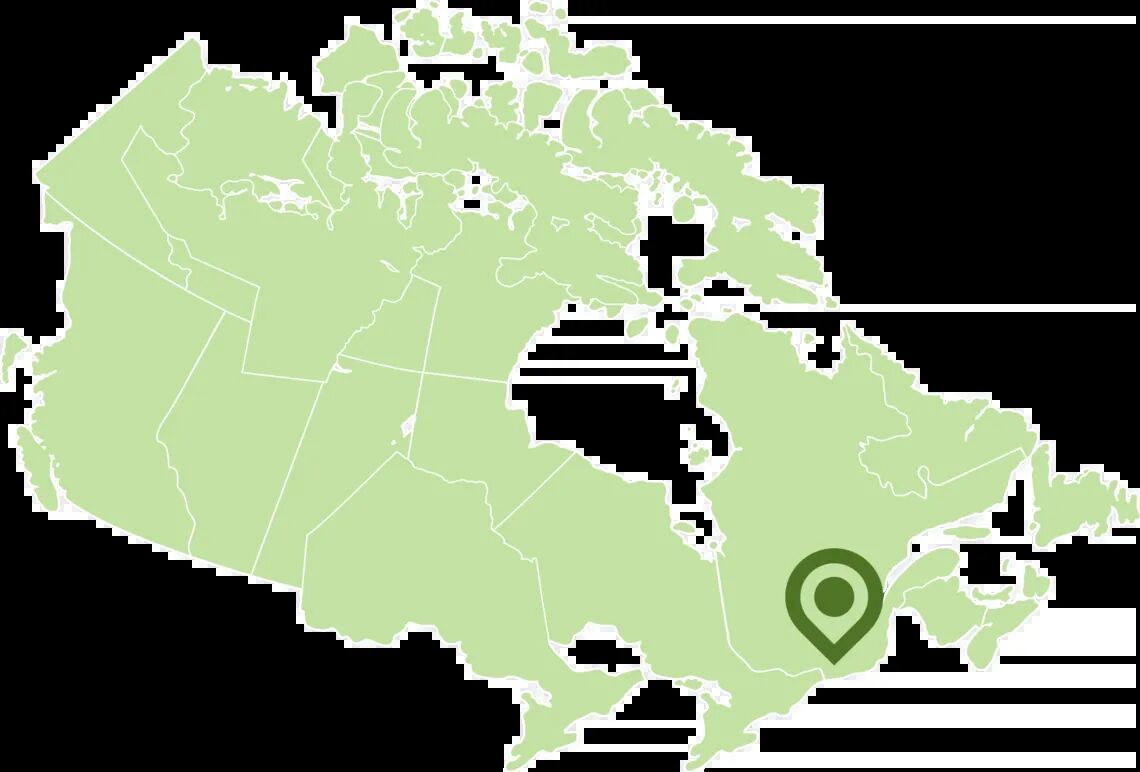

LOCATION 2

- Montreal, Quebec, Canada

PROJECT KEY FIGURES

- 2017-2018

TEAM

- 9-14 Quality Inspectors

- 1 Quality Manage

KEY ACHIEVEMENTS & RESULTS

- Over six months, TRIGO achieved a 67% reduction in defects

- Over twelve months, TRIGO achieved 97% quality level at the most problematic facility

- Reduced delivery delays by 90%

- Prevented further disciplinary actions, or termination, by OEM