Always in search of innovation and performance in quality management, TRIGO is diversifying its strategic areas of activity to take control of tomorrow's issues.

Through the acquisition of its subsidiary Scortex, a French start-up specialized in AI applied to automated quality control, TRIGO has strengthened its innovation division and is deploying its quality inspection services to new sectors.

Challenges

Industrial production, a complex and technological process, requires systematic or temporary visual inspections during its various phases to ensure the quality of the finished product.

Whether you are a manufacturer or an equipment supplier, quality management, while essential, is also a burden, especially when in-line inspection is still performed manually.

So how can you reduce the proportion of manual inspection, which is a more time-consuming solution?

How can we make compliance with quality standards even more reliable and ensure consistency between operators?

How do we optimize visibility and reactivity on quality issues, i.e., reduce the time spent on reporting management to focus on corrective actions?

Our Solutions

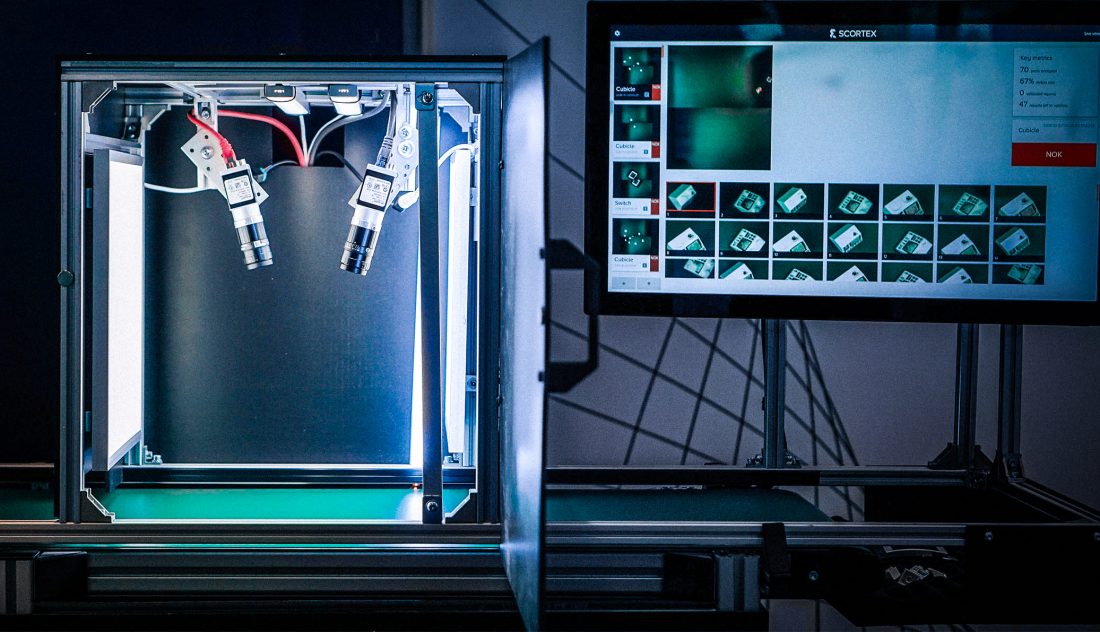

A new era begins with Spark! Scortex's solution, a TRIGO subsidiary dedicated to automated optical inspection (AOI), is a scanning technique based on the learning technology of Deep Learning.

Spark is a complete inspection solution, consisting of vision hardware, its connected platform and its Deep Learning inspection software*. The installation of Spark has been designed to be flexible and fast by adapting to many on and off-line inspection configurations.

Setting up an inspection application has been radically simplified. Spark has an intuitive interface that allows your teams a great deal of autonomy in setting up and evolving your inspections. You have control over performance.

The advantage of SPARK?

The competitive advantage of Spark is on several levels:

- The installation of Scortex inspection stations is extremely fast. The compliance learning system is almost immediate: 30 compliant parts are enough for Spark to reliably recognize quality defects in a batch of parts.

- The inspection process works fast, up to 3 parts per second.

- Get better inspection performance with Scortex's deep learning technology. Inspections on cosmetic and subjective criteria can also be solved. For example, scratches, bumps and stains that are difficult to see with the naked eye are now detected. Spark increases the reliability of the inspection and extends the range of automatable inspections.

- Spark is a preventive, flexible and modular quality control tool that requires minimal training. The user interface is understandable by all for optimal reactivity and maintainability.

- A solution focused on quality data. You have real-time access to all qualitative and quantitative inspection data, saving considerable time for your quality reporting and root cause analysis.

This solution, which is already used by many customers, allows you to automate your inspections, making them reliable and scalable. An automation that used to take several months, now takes a few hours.

Toly reduces waste through the AI-powered Spark technology

Explore how Toly, a leader in cosmetic packaging manufacturing, has automated its quality control by implementing Spark. In this video, Olaf Zahra, the Technical and Sustainability Director at Toly, explains the reasons behind this decision, and the results achieved thanks to the AI-driven automated quality inspection system from Scortex, a TRIGO company.

Spark in numbers:

- 30 compliant parts to create a new inspection

- 5 minutes to create a new application

- 3 parts per second: that's Spark's inspection rate

Millions of parts have already been inspected by Spark at 20 sites across Europe!